Petroleum coke is a product of crude oil that is distilled to separate light and heavy oils, and the heavy oils are then thermally cracked. From the appearance point of view, the coke has an irregular shape and different size black lumps (or particles), with metallic luster, the coke particles have a porous structure, the main element is carbon, which occupies more than 80% by weight, and the rest are elements of hydrogen, oxygen, nitrogen, sulfur and metals. Petroleum coke has its unique physical, chemical and mechanical properties. It is the non-volatile carbon of the heat generating part. The indicators of volatile and mineral impurities (sulfur, metallic compounds, water, ash, etc.) determine the chemical properties of coke.

Needle coke: have obvious needle structure and fiber texture, majority applied as high power graphite electrode in steel-making. For needle coke has strict quality requirement in sulfur content, ash content, volatile and true density etc, so that there are special requirement for needle coke’s processing art and raw material.

Sponge coke: high chemical reactivity, low impurity content, mainly used in aluminum industry and carbon industry.

Shot coke or globular coke: cylindrical spherical shape, the diameter of 0.6-30mm, usually produced by a high-sulfur, high asphalting residue, it can only be used for power generation, cement and other industrial fuel.

Powder coke: produced through fluidized coking processing, particles are fine (diameter of 0.1-0.4mm), high volatile and thermal expansion coefficient makes it cannot be directly used in electrodes and carbon industry.

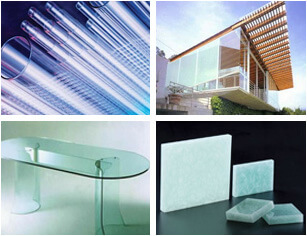

The main area of application of petroleum coke is the electrolytic aluminum industry, which accounts for more than 65% of the total consumption of petroleum coke, followed by coal, industrial silicon and other foundry industries. The use of petroleum coke as a fuel is mainly found in cement, power generation, glass and other industries. The glass industry is an energy-intensive industry, the fuel cost of the glass cost accounts for about 35%-50%.

The application of petroleum coke powder in glass industry:

1.Once the glass melting furnace ignition, it cannot be turn off until the furnace overhaul (3--5 years), it must continue to add fuel to ensure the furnace temperature stays at thousands of degrees; so that usually most of the plant will have a spare mill to ensure that continued production.

2.Petroleum coke powder used in glass industry, fineness of 200 mesh D90.

3.Raw coke moisture content of 8% -15%, it is generally needed for drying before entering the mill.

4.End petroleum powder moisture content is as good as low, generally speaking open system is better on dewatering.

| Grindability factor(HGI) | Primary moisture(%) | End moisture(%) |

|---|---|---|

| >100 | ≤6 | ≤3 |

| >90 | ≤6 | ≤3 |

| >80 | ≤6 | ≤3 |

| >70 | ≤6 | ≤3 |

| >60 | ≤6 | ≤3 |

| >40 | ≤6 | ≤3 |

| 200 mesh D90 | |

|---|---|

| Raymond mill | Hongcheng Petroleum Coke Mill began to enter the petroleum coke pulverizing industry in 2008, and its market share has reached more than 90% so far. |

| Vertical mill | For large-scale production. |

The material is crushed by the crusher to the fineness that can enter the mill(15mm-50mm).

The crushed small pieces of material are sent to the storage hopper through the elevator,and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

Through classification, the coarse powder will return to main mill to grind again.

The powder that meets the fineness enters the dust collector through the pipeline with the air flow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged uniformly.