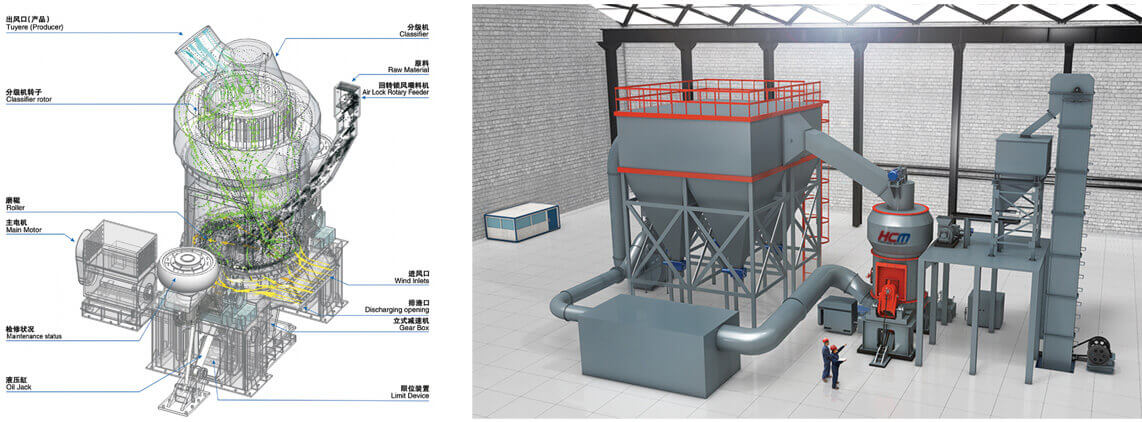

HLM vertical grinding mill and vertical roller mill is a high-efficiency energy-saving advanced pulverizing equipment integrating drying, pulverizing, grading and conveying, which has been researched and developed by Guilin Hongcheng Company for more than 20 years.

Hongcheng HLM vertical grinding mill has the advantages of high grinding efficiency, low power consumption, large feed particle size, easy adjustment of product fineness, simple equipment process, small footprint, low noise, small dust, convenient use and maintenance, and convenient operation. It has the advantages of low cost and low consumption of wear-resistant materials.

Max feeding size:50mm

Capacity: 10-150t/h

Fineness: 200-325 mesh (75-44μm)

Stable product quality. Because the material remains in the mill for a short time, the powder has a uniform particle shape and good fluidity. The iron content is very small and easy to remove, it has high whiteness and purity.

HLM series vertical grinding mill for super fine powders is equipped with: main mill, feeder, classifier, fan, piping, silo for material feeding, piping system, electrical cabinet, collector system, etc.

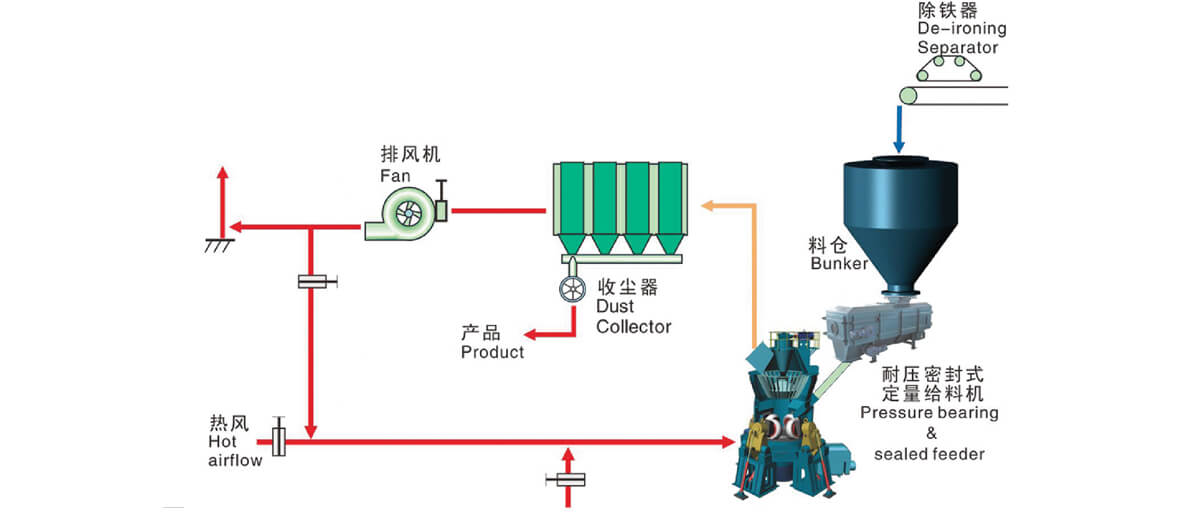

vertical grinding mill work process:

The motor drives the reducer to drive the grinding disc to rotate, and the material to be ground is fed into the center of the rotating grinding disc by the air-locking feeding device. Under the action of centrifugal force, the material moves to the periphery of the grinding disc and enters the grinding roller table.

Under the action of the pressure of the grinding roller, the material is crushed by extrusion, grinding and shearing.

At the same time, the wind is sprayed upwards evenly at a high speed from the air ring around the grinding disc, and the pulverized materials are blown up by the high-speed airflow at the wind ring,and the coarser material is blown back to the grinding disc for re-grinding, while the fine powder is brought in by the wind.

The grading machine is used for grading, and the qualified fine powder flows out of the mill along with the air flow, and is collected by the dust collection equipment to be the product. so the cycle completes the whole process of grinding operation.

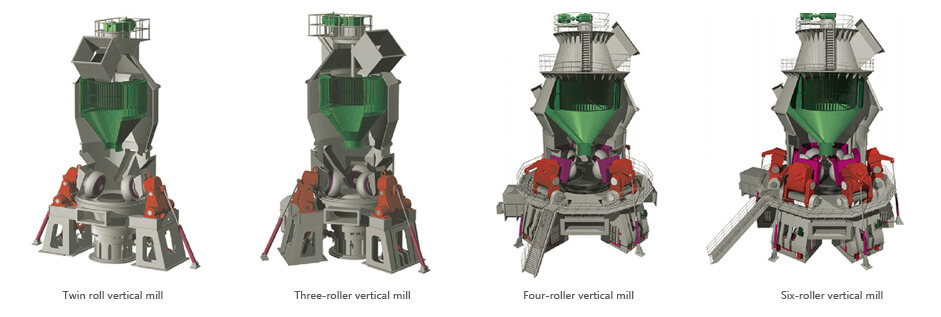

HLM vertical grinding mill adopts standard modular design to manufacture pressurizing device. As the capacity of the mill increases, the number of grinding rolls will increase accordingly (2, 3, 4 or 6 grinding rolls can be used) With fewer standard module components, a series of products with a variety of capabilities to meet the requirements of different processing of materials of different fineness and production capacity.

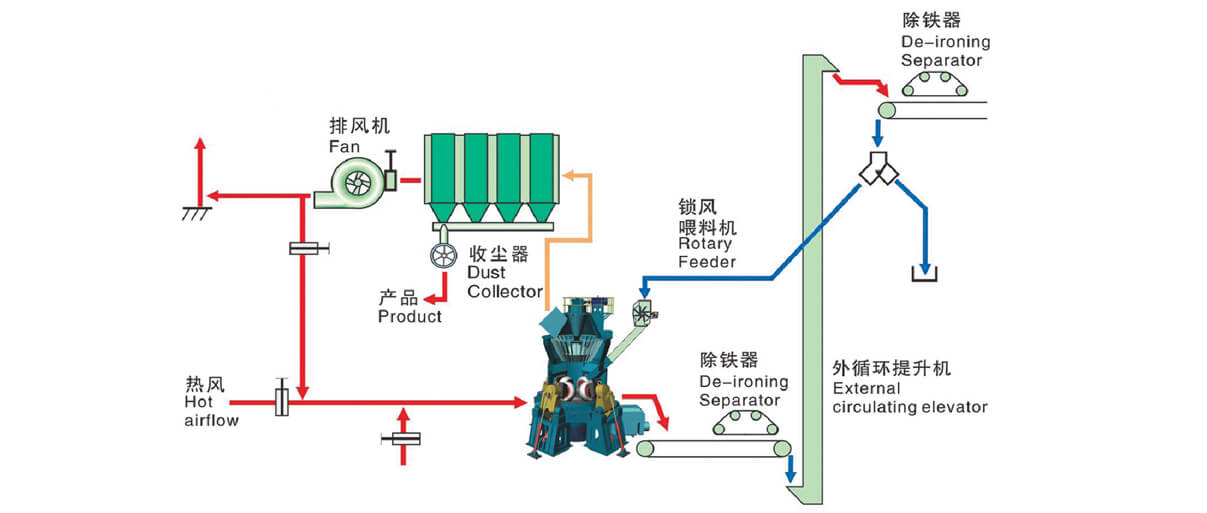

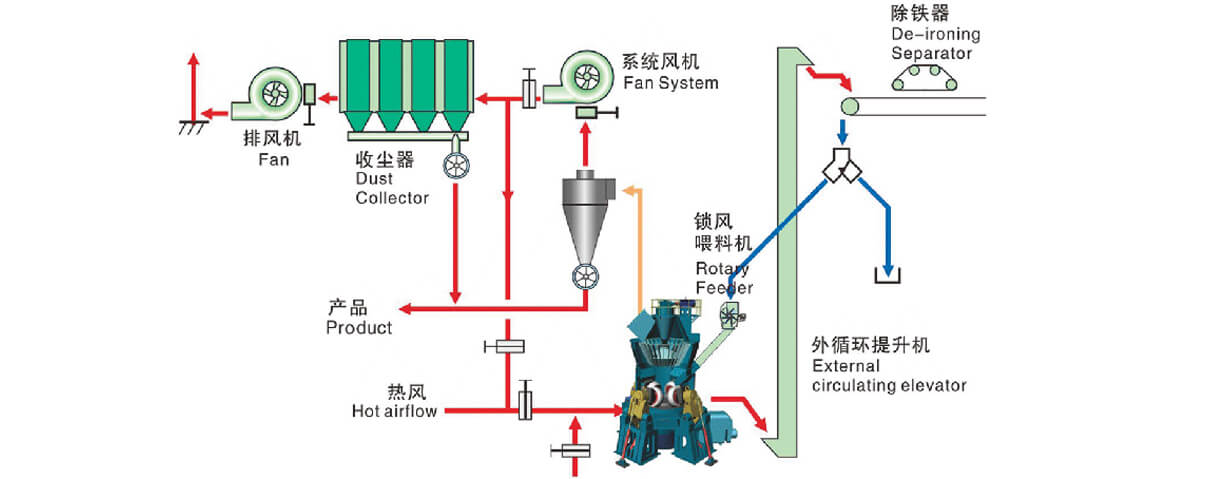

Dust Collection System

Single stage dust collection system I

Single stage dust collection system II

Secondary dust removal system

| Model | Grinding ring diameter(mm) | Capacity(t/h) | Feed Size | Raw material moisture | Fineness(10-40 μm) | Final Powder Moisture(%) | Power(kw) |

|---|---|---|---|---|---|---|---|

| HLM10/2X | 800 | 1-3 | 0-15 | <5% | <97% | ≤1 | 55 |

| HLM16/2X | 1250 | 2-7 | 0-20 | <5% | <97% | ≤1 | 132 |

| HLM17/2X | 1300 | 3-12 | 0-25 | <5% | <97% | ≤1 | 180 |

| HLM19/2X | 1500 | 4-16 | 0-35 | <5% | <97% | ≤1 | 250 |

| HLM21/2X | 1700 | 6-24 | 0-35 | <5% | <97% | ≤1 | 355 |

| HLM21/3X | 1750 | 7-27 | 0-35 | <5% | <97% | ≤1 | 400 |

| HLM24/2X | 1900 | 7-28 | 0-35 | <5% | <97% | ≤1 | 450 |

| HLM29/3X | 2400 | 9-35 | 0-40 | <5% | <97% | ≤1 | 560 |

| HLM29/4X | 2400 | 10-39 | 0-40 | <5% | <97% | ≤1 | 630 |

| HLM30/2X | 2800 | 11-45 | 0-50 | <5% | <97% | ≤1 | 710 |

Note: Raw Material Grinding Index≤18kWh/t。

| Model | Grinding ring diameter(mm) | Capacity(t/h) | Raw material moisture | Fineness | Power(kw) |

|---|---|---|---|---|---|

| HLM30/2 | 2500 | 85-100 | <10% | R0.008<12% | 800/900 |

| HLM34/3 | 2800 | 130-160 | <10% | 1120/1250 | |

| HLM42/4 | 3400 | 190-240 | <10% | 1800/2000 | |

| HLM44/4 | 3700 | 190-240 | <10% | 2500/2800 | |

| HLM50/4 | 4200 | 240-300 | <10% | 3150/3350 | |

| HLM53/4 | 4500 | 320-400 | <10% | 3800/4200 | |

| HLM56/4 | 4800 | 400-500 | <10% | 4200/4500 | |

| HLM60/4 | 5100 | 550-670 | <10% | 5000/5400 | |

| HLM65/6 | 5600 | 600-730 | <10% | 5600/6000 |

Note: Raw Material Grinding Index≤13kWh/t

| Model | Grinding ring diameter(mm) | Capacity(t/h) | Raw material moisture | Specific Surface Area | Power(kw) |

|---|---|---|---|---|---|

| HLM24/2P | 1900 | 35-45 | ≤2% | 220-260m2/kg(R0.08≤15%) | 560 |

| HLM26/2P | 2000 | 42-55 | ≤2% | 630 | |

| HLM30/2P | 2500 | 60-75 | ≤2% | 900 | |

| HLM34/3P | 2800 | 90-110 | <≤2% | 1400 | |

| HLM35/3P | 2800 | 130-160 | ≤2% | 2000 | |

| HLM42/4P | 3400 | 160-200 | ≤2% | 2500 | |

| HLM44/4P | 3700 | 190-240 | ≤2% | 3000 | |

| HLM45/4P | 3700 | 240-300 | ≤2% | 3800 | |

| HLM53/4P | 4500 | 300-380 | ≤2% | 4800 | |

| HLM56/4P | 4800 | 330-420 | ≤2% | 5300 |

Note: Raw Material Grinding Index≤18kWh/t

| Model | Grinding ring diameter(mm) | Capacity(t/h) | Raw material moisture | Specific Surface Area | Power(kw) |

|---|---|---|---|---|---|

| HLM26/S | 2000 | 15-18 | <15% | ≥420m2/kg | 560 |

| HLM30/2S | 2500 | 23-26 | <15% | 900 | |

| HLM34/3S | 2800 | 50-60 | <15% | 1800 | |

| HLM42/4S | 3400 | 70-83 | <15% | 2500 | |

| HLM44/4S | 3700 | 90-110 | <15% | 3350 | |

| HLM50/4S | 4200 | 110-140 | <15% | 3800 | |

| HLM53/4S | 4500 | 130-150 | <15% | 4500 | |

| HLM56/4S | 4800 | 150-180 | <15% | 5300 | |

| HLM60/4S | 5100 | 180-200 | <15% | 6100 | |

| HLM65/6S | 5600 | 200-220 | <15% | 6450/6700 |

Note: Raw Material Grinding Index≤25kWh/t

| Model | Grinding ring diameter(mm) | Capacity(t/h) | Raw material moisture | Coal Powder Fineness | Power(kw) |

|---|---|---|---|---|---|

| HLM10/2M | 800 | 3-5 | <15% | R0.08=10%-15% | 45/55 |

| HLM14/2M | 1100 | 7-10 | <15% | 90/110 | |

| HLM16/2M | 1250 | 9-12 | <15% | 110/132 | |

| HLM17/2M | 1300 | 13-17 | <15% | 160/185 | |

| HLM18/2M | 1300 | 14-19 | <15% | 185/250 | |

| HLM19/2M | 1400 | 18-24 | <15% | 220/250 | |

| HLM21/2M | 1700 | 23-30 | <15% | 280/315 | |

| HLM24/2M | 1900 | 29-37 | <15% | 355/400 |

| Model | Grinding ring diameter(mm) | Capacity(t/h) | Humedad de Materia Prima | Coal Powder Fineness | Power(kw) |

|---|---|---|---|---|---|

| HLM28/2M | 2200 | 36-45 | <15% | R0.08=10%-15% | 450/500 |

| HLM29/2M | 2400 | 45-56 | <15% | 560/630 | |

| HLM30/2M | 2500 | 45-56 | <15% | 710/800 | |

| HLM34/3M | 2800 | 45-56 | <15% | 900/1120 | |

| HLM42/4M | 3400 | 45-56 | <15% | 1400/1600 | |

| HLM45/4M | 3700 | 45-56 | <15% | 1800/2000 | |

| HLM50/4M | 4200 | 45-56 | <15% | 2500/2800 | |

| HLM56/4M | 4800 | 45-56 | <15% | 3150/3500 |

Note: Raw coal Hastelloy grindability coefficient 50~70