Coal, referred to as coal, is the remains of ancient plants, buried under the stratum, through the action of the pressure and temperature of the earth's crust to isolate the air, resulting in carbonized fossil minerals, black solid minerals composed of carbon, hydrogen, oxygen, nitrogen and other elements, mainly Mined by humans for fuel. At present, the proven coal reserves are more than 63 times the oil reserves. Coal is known as black gold, food for industry, and it is one of the main energy sources used by the human world since the 18th century. Coal was widely used as fuel for industrial production, which started from the industrial revolution at the end of the 18th century. With the invention and use of steam engines, coal was widely used as fuel for industrial production, bringing huge productivity to society.

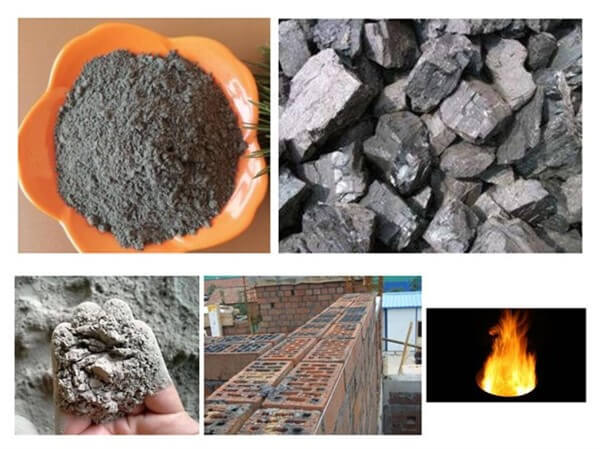

It is mostly lumpy, dark brown, dark shiny, and loose in texture; it contains about 40% volatile matter, has a low flash point and is easy to catch fire. It is generally used in industries of gasification, liquefaction, electric boiler, etc.

Generally granular, small block, powder, mostly black and shiny, fine texture, volatile content of more than 30%, low ignition point, easy to ignite; most bituminous coal is viscous and easy to slagging when burning. Used in coking, coal blending, electric boiler, gasification and other industries.

There are two kinds of powder and small pieces, black with metallic luster, slightly shiny. Less impurities, dense texture, high fixed carbon content, up to more than 80%; low volatile content, less than 10%, high ignition point, not easy to catch fire. It should be mixed with an appropriate amount of coal to reduce the fire. Can be used to make gas or directly used as fuel.

| 200 mesh D80-90 | Raymond mill | HC1700 and HC2000 Large Pendulum Mills perform low-input, high-yield production |

| Vertical mill | Large-scale production, the competitiveness of vertical mills above HLM1700 is obvious |

| HC Series | HC1300 | HC1700 | HC2000 |

|---|---|---|---|

| Capacity(t/h) | 3-5 | 8-12 | 15-20 |

| Main mill motor(kw) | 90 | 160 | 315 |

| Blower motor(kw) | 90 | 160 | 315 |

| Classifier motor(kw) | 15 | 22 | 75 |

| HLM Series | HLM1300 | HLM1500 | HLM1700 | HLM1900 | HLM2200 | HLM2400 | HLM2800 |

|---|---|---|---|---|---|---|---|

| Capacity(t/h) | 13-17 | 18-22 | 22-30 | 30-40 | 40-50 | 50-70 | 70-100 |

| Material moisture | ≤15% | ||||||

| Fineness | D80 | ||||||

| Product moisture | ≤1% | ||||||

| Main motor power(kw) | 160 | 250 | 315 | 400 | 500 | 630 | 800 |

The bulk material is crushed by the crusher to the fineness that can enter the mill(15mm-50mm).

The crushed small pieces of material are sent to the storage hopper through the elevator,and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

Through classification, the coarse powder will return to main mill to grind again.

The powder that meets the fineness enters the dust collector through the pipeline with the air flow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged uniformly.