HCH ultra fine ring roller mill is a new type of vertical roller mill successfully developed by Guilin Hongcheng with many years of production. The product fineness can reach D97≤5um at one time. HCH is a real energy-saving high-fine roller grinding mill that is especially suitable for deep processing of non-metallic minerals. After long-term market application practice and user verification, the HCH1395 model of this equipment has been certified by the China Calcium Carbonate Association as an energy-saving and consumption-reducing equipment in the field of high-fine processing of calcium carbonate in China. HCH2395 is also the largest high-fine ring roller mill in China at present.

Max feeding size:10mm

Capacity: 1-22t/h

Fineness: 5-45μm

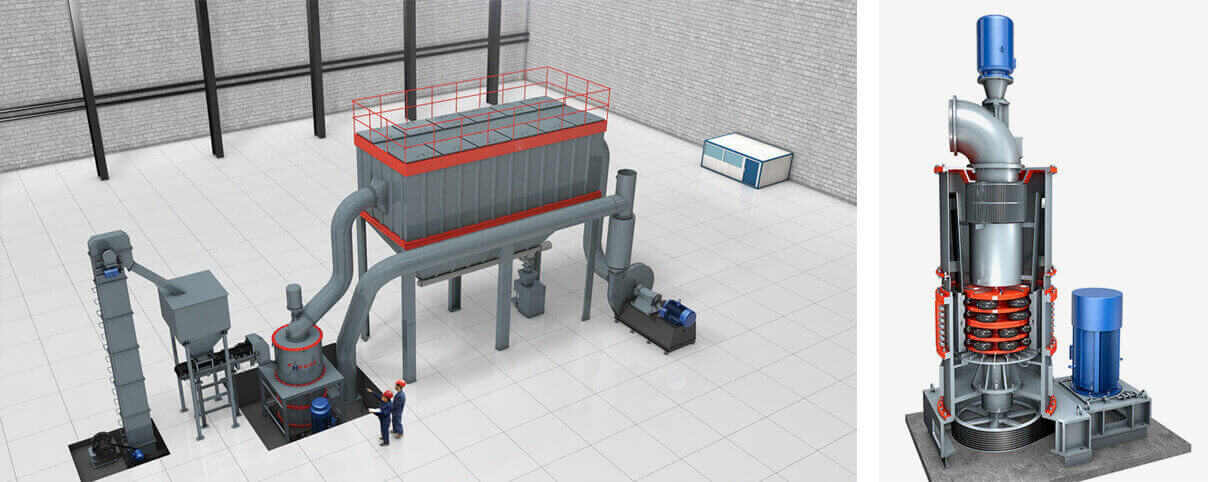

The complete system of HCH ultrafine ring roller mill is mainly composed of main engine, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc.

Process flow of milling system

The material is crushed by the jaw crusher into materials smaller than 10mm.

lifted by the bucket elevator to the storage hopper, and then quantitatively sent to the main cavity by the feeder for grinding.

The grinding roller installed on the turntable in the main machine cavity rotates around the central axis. There is a large movable gap between the grinding roller and the grinding roller pin. The grinding roller swings horizontally under the action of centrifugal force, so that the grinding roller presses the grinding ring. At the same time the grinding roller rotates around the grinding roller pin. The material passes through the gap between the grinding roller and the grinding ring, and is crushed and ground due to the rolling of the grinding roller. The grinding roller is divided into 4 layers (HCH780 is arranged in 3 layers), and the material is ground by the first layer of grinding roller. The middle ring is crushed once, then the second, third, and fourth layers are crushed a second, three, and four times. Therefore, the material is sufficiently pulverized and ground, and the obtained product has fineness.

The ground powder falls to the chassis under the action of gravity, and is blown to the classifier above the main machine for screening under the action of the fan. Air flows into the pulse dust collector. The collected product is discharged through the discharge valve.

The purified air flows into the blower through the remaining air duct above the pulse dust collector. The air path is circular. The airflow in the road is negative pressure, and the indoor sanitary conditions are better. Since the moisture contained in the material is heated and evaporated into gas during the grinding process, the gas leaking from the flange joint and the feed port in the pipe leads to an increase in the air volume in the circulating air path, and these increased air volumes are between the blower and the host transmitted and released into the atmosphere.

| Model | Feed size(mm) | Fineness(mm) | Capacity(t/h) | Weight(t) | Power(kw) |

|---|---|---|---|---|---|

| HCH780 | ≤10 | 0.04-0.005 | 0.7-3.8 | 17.5 | 144 |

| HCH980 | ≤10 | 0.04-0.005 | 1.3-6.8 | 20 | 237 |

| HCH1395 | ≤10 | 0.04-0.005 | 2.6-11 | 44 | 395 |

| HCH2395 | ≤10 | 0.04-0.005 | 5-22 | 70 | 680 |