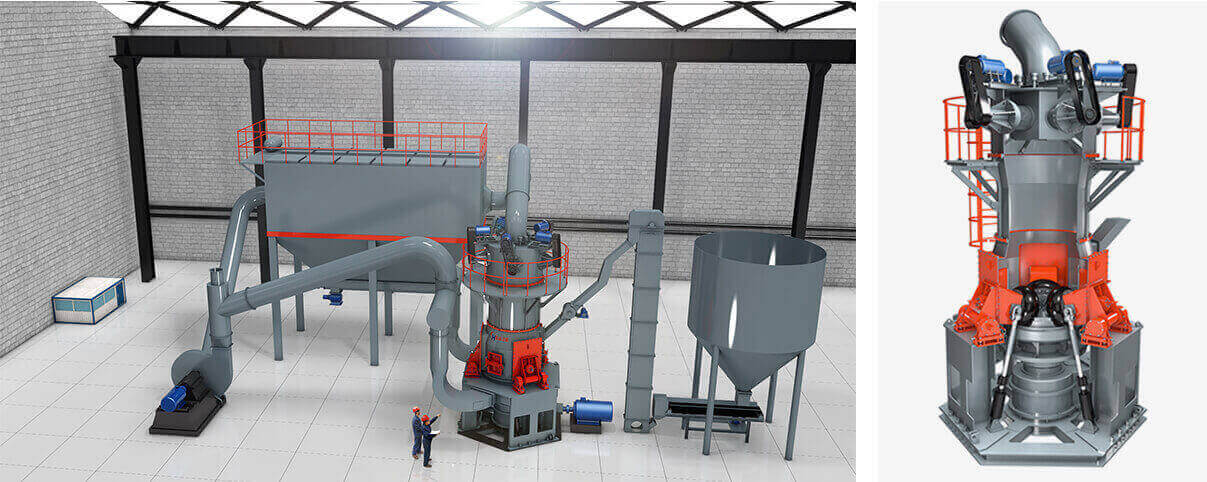

HLMX ultrafine grinding mill, ultrafine vertical mill is independently developed by our engineers in response to the needs of the non-metallic powder scale production industry. HLMX series vertical mill for superfine powder with static and dynamic separator, can produce the powder with adjustable fineness from 325 mesh(40μm) to 2500 mesh(5μm), production capacity reaches 40T/H. Its high efficiency, low consumption, is environment friendly, widely used to crush limestone, calcite, calcium carbonate, kaolin, marble, barite, bentonite, pyrophyllite etc.

Max feeding size:20mm

Capacity: 4-40t/h

Fineness: 325-2500 mesh

Stable product quality and excellent quality. The material remains in the mill for a short time, which makes it easier to detect the particle size distribution and composition of the product and reduces repeated grinding. The final product contains less iron, and has high brightness and purity.

Easy maintenance and low operating cost. The grinding roller can be taken out of the machine by hydraulic device, it is convenient for maintenance; the roller cover can be flipped over and used, which extends the service life. The mill can be started without materials, eliminating start-up problems.

HLMX Ultrafine Vertical Mill is equipped with: main mill, feeder, classifier, fan, piping, silo for material feeding, piping system, electrical cabinet, collector system, etc.

work process:

The motor drives the reducer to drive the grinding disc to rotate, and the material to be ground is fed into the center of the rotating grinding disc by the air-locking feeding device. Under the action of centrifugal force, the material moves to the periphery of the grinding disc and enters the grinding roller table.

Under the action of the pressure of the grinding roller, the material is crushed by extrusion, grinding and shearing.

At the same time, the wind is sprayed upwards evenly at a high speed from the air ring around the grinding disc, and the pulverized materials are blown up by the high-speed airflow at the wind ring,and the coarser material is blown back to the grinding disc for re-grinding, while the fine powder is brought in by the wind.

The grading machine is used for grading, and the qualified fine powder flows out of the mill along with the air flow, and is collected by the dust collection equipment to be the product. so the cycle completes the whole process of grinding operation.

When the iron and other sundries mixed into the material move to the edge of the grinding table with the material, due to its large weight, it cannot be blown up by the wind, and falls into the lower cavity of the mill and is scraped into the slag discharge port by the scraper to be discharged, which can effectively ensure the quality of the finished product.

The rotor speed of the multi-head powder separator is easy to adjust, and qualified products of various specifications can be obtained.

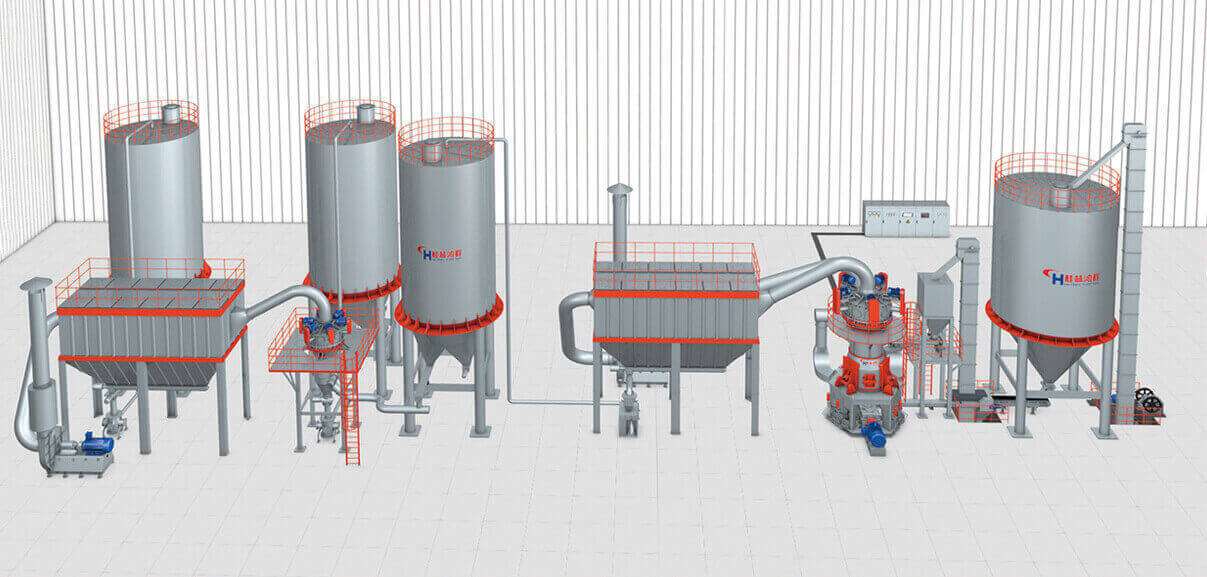

The secondary classification system is composed of ultra-fine classifiers, fans, dust collectors, silos, screw conveyors, pipes and other equipment. The ultra-fine classifier is its core equipment.

HLMX series vertical ultrafine mills are equipped with a secondary air separation classification system, which has high dust separation efficiency and can effectively separate coarse and fine powders. The separation fineness can be as high as 3μm, and qualified products of various specifications can be obtained.

Characteristics of the secondary classification

High classifying efficiency: Classifier and fan are controlled by frequency conversion speed regulation. By adjusting the speed of classifier and fan impeller, the fineness of finished products with different specifications and stability can be quickly obtained.

Dust separator: high efficiency and energy saving dust separator. Single or multi-head dust separators can be used, and the fineness of the finished product can be adjusted.

The fineness range of the finished product is wide: the fine particles of the material ground by the vertical mill can be classified, and the classification fineness ranges from 3um to 45um. It can produce products of different specifications with a vertical mill, and it can also produce products of the same fineness quickly and stably.

| Model | Grinding ring diameter(mm) | Feed Moisture | Fineness | Capacity(t/h) |

|---|---|---|---|---|

| HLMX1000 | 1000 | ≤5% | 7μm-45μm Finest can reach 3μm (With multihead classifier system) | 3-12 |

| HLMX1100 | 1100 | ≤5% | 4-14 | |

| HLMX1300 | 1300 | ≤5% | 5-16 | |

| HLMX1500 | 1500 | ≤5% | 7-18 | |

| HLMX1700 | 1700 | ≤5% | 8-20 | |

| HLMX1900 | 1900 | ≤5% | 10-25 | |

| HLMX2200 | 2200 | ≤5% | 15-35 | |

| HLMX2400 | 2400 | ≤5% | 20-40 |