Talc is a kind of silicate mineral, belongs to trioctahedron mineral, the structural formula is (Mg6)[Si8]O20(OH)4. Talc generally in bar, leaf, fiber or radial pattern. The material is soft and creamy. The Mohr’s Hardness of talc is 1-1.5. A very complete cleavage, easily split into thin slices, small natural angle of repose (35 ° ~ 40 °), very unstable, wall rocks are slippery and silicified magnesite petrochemical, magnesite rock, lean ore or dolomitic marble rock, generally not stable except for a few which are medium; joints and fissures, physical and mechanical properties of wall ores affect of the rock mining technology is great.

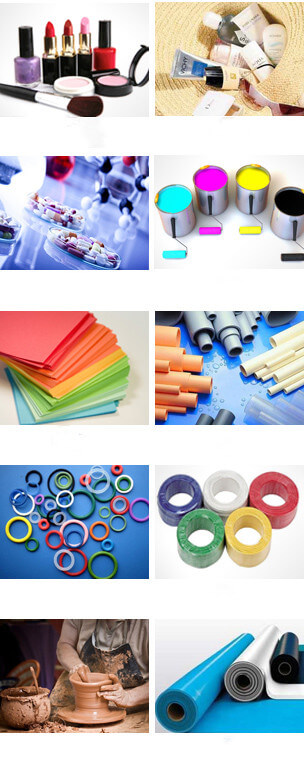

Talc has high performances of lubricity, sticky resistance, flow-aiding, fire resistance, acid resistance, insulativity, high melting point, inactive chemical property, good covering power, soft, good gloss, strong adsorption. So, talc has wide application in cosmetic, medicine, paper making, plastic and other fields.

applied in skin moisten, after shave powder, talcum powder. Talc has the function of obstructing infrared ray, so it can improve the performance of cosmetics.

applied in medicine tablets and powder sugar-coating, prickly heat powder, Chinese medicinal formulae, food additives, etc. The material has the advantages of non-poisonous, tasteless, high whiteness, good glossiness, soft flavor and high smoothness.

applied in white pigment and industrial coating, base coating and protective paint, stability of the paint can be increased.

used as the filler of paper and paperboard. The paper product can be smoother and finer. It can also save up raw material.

used as the filler of polypropylene, nylon, PVC, polyethylene, polystyrene and polyester. Talc can increase the tension strength, shearing strength, twisting strength and pressuring strength of plastic product.

used as filler and adhesive of rubber.

used to increase cable rubber performance.

applied in electro-ceramic, wireless ceramic, industrial ceramic, construction ceramic, domestic ceramic and ceramic glaze.

applied in waterproof roll, waterproof coating, waterproof ointment, etc.

Talc powder processing is generally divided into fine talc powder processing (20 mesh-400 mesh), ultra-fine talc powder processing (400 mesh-1250 mesh), and micropowder processing (1250 mesh-3250 mesh).

| SiO2 | MgO | 4SiO2.H2O |

|---|---|---|

| 63.36% | 31.89% | 4.75% |

| Product fineness(mesh) | 400 mesh D99 | 325 mesh D99 | 600 mesh, 125 mesh, 800 mesh D90 | 1250-2500 mesh |

|---|---|---|---|---|

| Model | Raymond mill or ultrafine roller mill | |||

The bulk material is crushed by the crusher to the fineness that can enter the mill(15mm-50mm).

The crushed small pieces of material are sent to the storage hopper through the elevator,and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

Through classification, the coarse powder will return to main mill to grind again.

The powder that meets the fineness enters the dust collector through the pipeline with the air flow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged uniformly.