Bentonite is a clay mineral with montmorillonite as the main component, its chemical composition is quite stable and it is known as the universal stone. Montmorillonite is one of the typical layered silicate minerals, but it differs from other layered silicate minerals in that the spaces between the layers are particularly large, so that the layers can contain an indefinite amount of water. Exchangeable molecules and cations. The slow diffractometer scan test results show that the particle size of montmorillonite is close to the nanometer level and it is a natural nanomaterial.

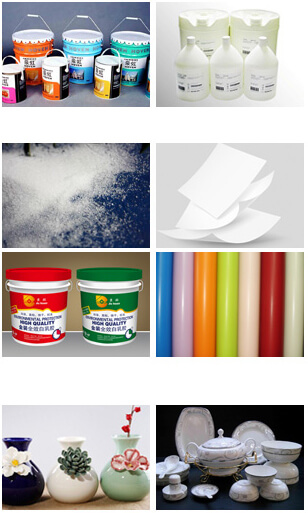

Mainly used in various casting coatings and various ceramic glaze coatings, as a suspending agent and thixotropic agent for the base material. It is used in daily chemicals such as latex paint, as thixotropic agent, latex stabilizer and thickener for suspoemulsion and paste, and can also be used as fabric sizing agent.

① In the mechanical casting industry, it can be used as casting sand and binder, which can overcome the phenomenon of sand inclusion and skinning of castings, reduce the rejection rate of castings, and ensure the accuracy and smoothness of castings.

② In the paper industry, it is used as a filler for paper to enhance the brightness of paper.

③Using the strong bonding properties of this product, it is used in the production of white latex, floor glue, paste, etc.

④ Because of its stable suspension and thickening properties, it can effectively float and disperse powders, and can be used as thickening and anti-settling additives for water-based coatings.

⑤ At the same time, it can be used as sodium soil for drilling mud due to its excellent dispersibility and expansion, high pulping rate, low water loss, colloidal properties and shear dilution ability.

Adding this product in the production of ceramic technology increases the plasticity and strength of the embryo body or glaze, greatly increases the lubricating effect, and is beneficial to ball milling. In addition, the suspension and stability are greatly enhanced, the porcelain is fine and the color is soft. The glaze machine is smooth , Good light transmittance, anti-collision and certain mechanical strength.

1.Used for animal and vegetable oil refining, able to remove harmful composition in edible oil;

2.Used for petroleum and mineral refining and purifying;

3.In food industry, used as clarifying agent of wine, beer and juice;

4.Applied as catalyst, filler, drying agent, adsorbent and flocculating agent in chemical industry;

5.Can be applied as chemical defense antidote in national defense and chemical industry. Along with the development of society and science, activated clay will have a wider application.

Can be applied as foundry molding sand, binder and radioactive waste absorbent; Also can be used as thinner and pesticide in agriculture.

| Name | SiO2 | AL2O3 | Fe2O3 | FeO | TiO3 | K3O | Na2O | CaO | MgO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| Bentonite | 67.75 | 15.55 | 4.25 | <0.01 | 0.58 | 1.65 | 2.89 | 0.35 | 2.59 | 5.28 |

| Fineness(mesh) | 200 mesh D95 | 250 mesh D90 | 325 mesh D90 |

|---|---|---|---|

| Model | HC series mill for large size bentonite | ||

The material is crushed by the crusher to the fineness that can enter the mill(15mm-50mm).

The crushed small pieces of material are sent to the storage hopper through the elevator,and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

Through classification, the coarse powder will return to main mill to grind again.

The powder that meets the fineness enters the dust collector through the pipeline with the air flow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged uniformly.