In recent years, the amount of slag treatment has been increasing. According to environmental protection requirements, secondary utilization is required, and solid waste resources are rationally utilized. So what manufacturers sell solid waste vertical mill equipment? How much does it cost to invest in a vertical mill with an annual output of 500,000 tons of slag?

hlm slag vertical mill, welcome to leave a message or consult [email protected]

1. Vertical mill helps solid waste to turn waste into treasure

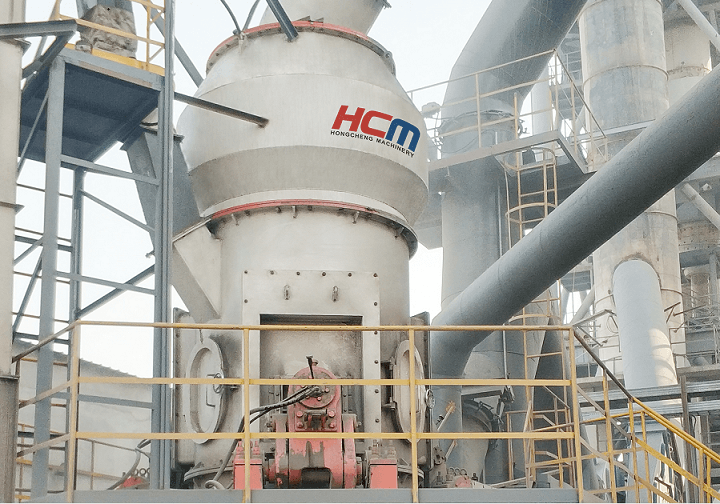

The value of solid waste slag recycling continues to rise, and it is necessary to use more professional solid waste slag vertical mill equipment to achieve midwifery. Guilin Hongcheng has always paid attention to the grinding needs of the solid waste industry, and has devoted itself to research and development of professional vertical mill equipment that meets the needs of industry development, helping solid waste projects turn waste into treasure and create greater value.

The new environment-friendly vertical mill equipment integrates crushing, drying, grinding, grading and powder collection, and the equipment process is scientific. Moreover, the whole machine has high grinding efficiency, large production capacity, and low energy consumption. It breaks through the disadvantages of traditional grinding machines and has always been a new type of grinding equipment favored by the solid waste field. With the advantages of high performance, large production capacity, environmental protection and energy saving, it helps solid waste projects turn waste into wealth and create greater value.

Guilin Hongcheng environmental protection mill: HLM vertical mill

{Finished Particle Size}: 22-180μm

{Production output}: 5-700t/h

{Application range}: Electric power, metallurgy, rubber, paint, plastic, pigment, ink, building materials, medicine, food and other fields are all widely used fields of vertical mill equipment.

{Applied Materials}: It is very suitable for grinding non-metallic minerals such as calcium carbide slag, lignite, chalk, cement clinker, cement raw meal, quartz sand, steel slag, slag, pyrophyllite, and iron ore. The fineness of the product is easy to adjust and the operation is simple.

{Grinding characteristics}: It has a very strong adaptability to extremely difficult to grind, easy to grind, high humidity, and dry materials. It has a wide range of grinding fields and a variety of grinding types.

2. Does Hongcheng have any solid waste cases?

We have been deeply plowing and developing in the field of solid waste slag, and have undertaken many solid waste slag grinding cases. Customers and friends can visit and inspect the factory at any time to understand the special vertical mill equipment and provide complete grinding needs, such as fine grinding Information such as degree, production capacity, region, etc., to obtain the selection and configuration plan and product quotation you require.

3. Customer Feedback

After years of development, Hongcheng has a very good market reputation and has always been a representative enterprise in the industry. Grinding customers from different regions commented that Hongcheng Mill has good quality, excellent quality, and long service life of the equipment. Whether it is product quality or equipment selection and quotation, it is based on the customer's point of view to meet customer needs. Escort for customers to increase production. Thank you for your support and trust, your affirmation and praise are the greater motivation to support our progress and development.

Guilin Hongcheng is a benchmark enterprise in the field of mine milling equipment. The ore mills produced by Guilin Hongcheng are rich in variety, excellent in quality, sufficient in spare parts supply, high in production and efficiency, energy saving and environmental protection. For different milling customers, we can provide milling equipment of various specifications and models with output ranging from 1 ton to 300 tons. Hongcheng's new vertical mill equipment is an advanced equipment to meet the production increase of solid waste residue projects. Guilin Hongcheng has rich experience and provides the industry with an annual output of 500,000 tons of slag vertical mill, helping the slag grinding processing project to bring greater benefits.