Promoting development with ecology, protecting the environment and promoting economy, environmental protection has become a people's livelihood issue that the country focuses on. The environmentally friendly mill is based on environmental protection, processing and producing various minerals, with small footprint, energy saving and consumption reduction, stable operation, low noise and less dust, mainly include Raymond mill, vertical mill, ultra-fine vertical mill, ultra-fine ring roller mill and other mills.

1. Raymond Mill

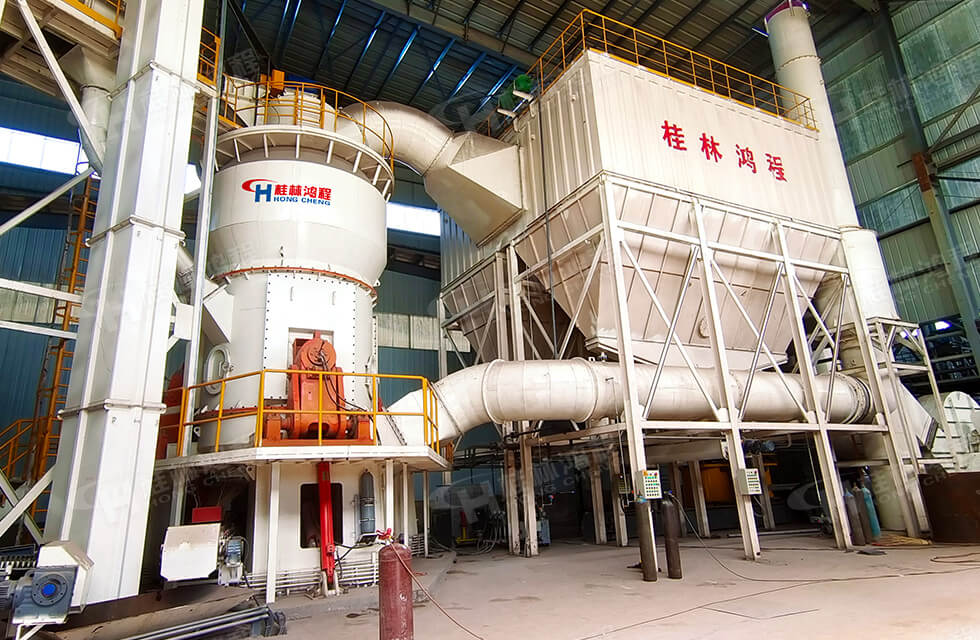

The fineness of the Raymond mill is 38-180μm, the production capacity is 1-90t/h, and the output is 30-40% higher than that of the traditional Raymond mill. The Raymond mill produced by Guilin Hongcheng is updated on the basis of the original Raymond mill. The grinding method is changed to pendulum grinding, which has large output, high stability and good shock absorption effect. Compared with the traditional R-type Raymond mill, the production capacity and environmental protection are improved.

Raymond mill case site, welcome to leave a message or consult [email protected]

Production capacity: 1—90t/h

Finished product fineness: 38—180μm

Scope of application: Limestone, calcite, dolomite, kaolin, bauxite, marble, feldspar, barite, phosphate rock, clay, graphite, kaolin, wollastonite, etc. Mohs hardness below 7, humidity within 6% of various non-flammable and explosive materials.

Application fields: Desulfurization of power plants, manganese industry, pulverized coal

2. Vertical Mill

Compared with Raymond mill, vertical mill is a rising star. Although its production is relatively late, because of its advantages of large-scale, intelligent and large-scale powder processing, it focuses on slag, coal gangue, steel slag and pulverized coal. Solid waste such as ash, industrial by-product gypsum, construction waste, metallurgical waste slag, etc., provides an effective utilization method for the treatment of solid waste, and has become the mainstream equipment selected by environmental protection pulverizers. Its production capacity: 1-200t/h, finished product particle size: 22-180μm.

vertical mill case site, welcome to leave a message or consult [email protected]

Production capacity: 1—200t/h

Particle size of finished product: 22—180μm

Scope of application: Cement raw meal, desulfurized limestone, slag, steel slag, manganese ore, coal mine, phosphate rock and other materials

Application fields: Electric power, metallurgy, solid waste treatment, cement, chemical industry, non-metallic minerals and other industries

3. Ultrafine Vertical Mill

The particle size of the ultra-fine vertical mill is 3-22μm, and the production capacity is 1-50t/h, which breaks the bottleneck of difficult large-scale production of ultra-fine powder processing. It is easier to form a material layer, and the grinding efficiency is high. The production of products of the same fineness grade can save 30%-50% of energy compared with ordinary pulverizers. The grinding rollers and grinding discs made of special materials have a long service life. The entire equipment adopts the national patented technology for dust collection. the dust collection rate reaches 99.9%.

ultrafine vertical mill case site, welcome to leave a message or consult [email protected]

Production capacity: 1—50t/h

Particle size of finished product: 3—22μm

Scope of application: Ultrafine powder processing of ultrafine calcium carbonate, calcite, kaolin, marble, limestone, graphite, gypsum, pyrophyllite, barite and other non-metallic minerals

Application field: Paper, coating, plastic, rubber, ink, chemical and other industries

4. Ultrafine Ring Roller Mill

The equipment not only has the advantages of high efficiency and low consumption of high-speed impact mill, but also has the fineness close to that of jet mill. The product fineness can reach D97≤10μm at one time. It is a real economical and practical energy-saving and consumption-reducing equipment. It can be used for limestone, talc, calcium carbonate, calcite, kaolin, graphite, etc. Mohs hardness below 7, humidity within 6% Ultrafine crushing of various non-metallic minerals.

ultrafine ring roller mill case site, welcome to leave a message or consult [email protected]

Production capacity: 1—11t/h

Particle size of finished product: 5—38μm

Scope of application: Limestone, talc, calcium carbonate, calcite, kaolin, graphite, dolomite, potassium feldspar, bentonite and other non-metallic minerals with Mohs hardness below 7 and humidity within 6%

Applications: Papermaking, power plant desulfurization, plastics and other industries

Which brand of specific environmental protection mill is good? We recommend Guilin Hongcheng. Guilin Hongcheng has all the above equipment, and there are many models to choose from. The wearing parts are of high quality, wear-resistant and corrosion-resistant, and the whole machine has a long service life. , Among many manufacturers of environmentally friendly mills, Guilin Hongcheng has a world-renowned reputation and is a product worthy of customer trust. If you want to know more, please feel free to consult online.