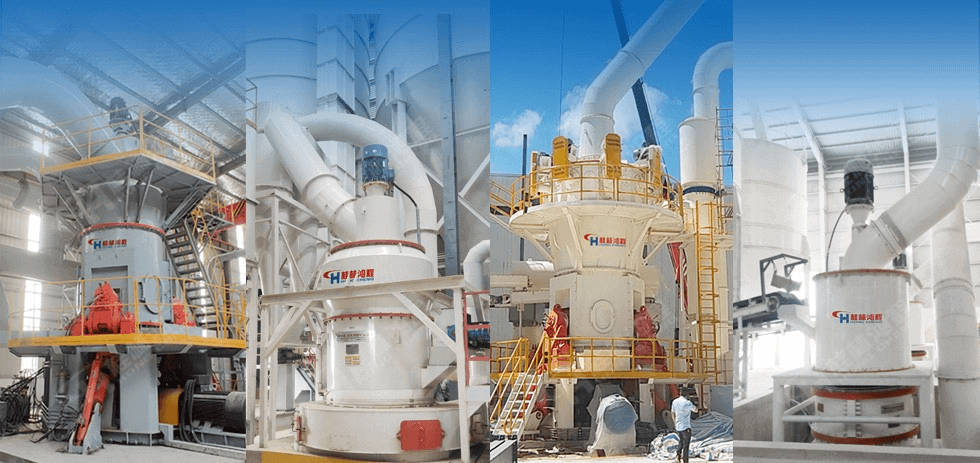

What is the output of heavy calcium carbonate grinding? Which grinding equipment is better to use? Guilin Hongcheng, as an influential mill manufacturer, after years of research and development, heavy calcium carbonate mills include Raymond mill, vertical mill, ultra-fine vertical mill, ultra-fine ring roller mill powder machine. The following introduces the characteristics of these several types of grinding equipment. Friends can compare and see which model is suitable according to the actual situation. You can also leave a message for consultation. Hongcheng has a professional solution team to provide you with one-to-one service.

What is the output of heavy calcium carbonate grinding, welcome to leave a message or consult [email protected]

1. Raymond Mill

[HC large pendulum mill] is innovatively developed on the basis of traditional mills. It is an advanced equipment for large-scale powder processing with large production capacity, high cost performance, stable operation and convenient maintenance. The equipment is highly systematic and can form an independent and complete production system, including crushing, conveying, pulverizing, product collection, storage and packaging. , white jade, titanium dioxide, quartz stone, bauxite, marble and other non-metallic minerals grinding and processing, the equipment covers a number of invention patents, the fineness of the finished product can be adjusted between 80-400 mesh, and the output can reach each 1-90 tons per hour, stable product performance, leading milling technology, solid and reliable structure, strong shock resistance, good dust collection effect, high classification efficiency, and convenient maintenance. It is widely used in metal ores, non-metallic minerals, medicinal materials, food, etc. advanced equipment in the field.

2. Vertical mill

[HLM super-large vertical mill] is a large-scale milling production equipment carefully developed by Guilin Hongcheng. This equipment focuses on the milling field, with strong adaptability to materials, advanced milling technology, high efficiency, energy saving and environmental protection, A wide range of grinding fields, with unique structural advantages, mainly composed of main machine collector, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc. The current situation of powder, Hongcheng vertical mill equipment integrates drying, grinding, grading and conveying, and is widely used in electric power, metallurgy, cement, chemical and other industrial fields. The fineness range of the finished product can be adjusted between 80-600 mesh, and the output It can reach 1-200 tons per hour. Guilin Hongcheng has pioneered research and development of drying, grinding, grading and conveying based on the development trend of the industry, aiming at the bottleneck of traditional pulverizers with low output, high energy consumption and high maintenance costs. The integrated HLM vertical pulverizer has set off a frenzy of imitation in the field of large-scale pulverizing, and has become the mainstream equipment in the pulverizing field of coal mines, cement, slag, and non-metallic ores.

3. Ultrafine vertical mill

[HLMX large-scale ultra-fine vertical mill] is an advanced equipment carefully developed by Guilin Hongcheng based on the field of non-mineral large-scale ultra-fine milling. With scientific and reasonable product structure and advanced milling technology, it is widely used in metallurgy , chemical, power plant desulfurization, pulverized coal preparation and other fields, is a high-yield, high-efficiency, environmental protection and energy-saving ultra-fine powder processing equipment. The fineness range of the finished product can be adjusted between 325-400 mesh, and the output can reach 1-90 tons per hour. It is a new type of energy-saving and environmentally friendly grinding equipment. The system is integrally sealed and operates under full negative pressure. No dust spillage, it is an advanced equipment in the field of non-mineral large-scale pulverizing.

4. Ultrafine Ring Roller Mill

[HCH Ultrafine Ring Roller Mill] is an economical and practical ultrafine powder processing equipment in Guilin Hongcheng. According to the processing characteristics of non-mineral ultrafine powder, the equipment has comprehensive mechanical crushing performance such as rolling, grinding and clustering. It is especially suitable for deep processing of non-minerals such as dolomite, potassium feldspar, bentonite, kaolin, graphite, etc. It is a superfine powder processing equipment widely used in chemical, metallurgy and other industrial fields. The fineness range of the finished product can be adjusted between 325 mesh and 2500 mesh, and the output can reach 1-22 tons per hour. It is in line with the development needs of the field of non-metallic ore ultrafine powder preparation. Large ratio, high energy utilization rate, low wear and tear, compact structure, long product service life, low comprehensive investment cost, and create greater market value for customers with excellent advanced technical advantages and first-class services.

There are many models of heavy calcium carbonate grinding mills. The amount of heavy calcium carbonate grinding output depends on what model is used. The above introduces the characteristics of various grinding models, the range of grinding fineness and the output. , which can be selected according to production needs. If you want to know more about the output of heavy calcium carbonate grinding, what kind of grinding machine is used for grinding, please leave a message for consultation.