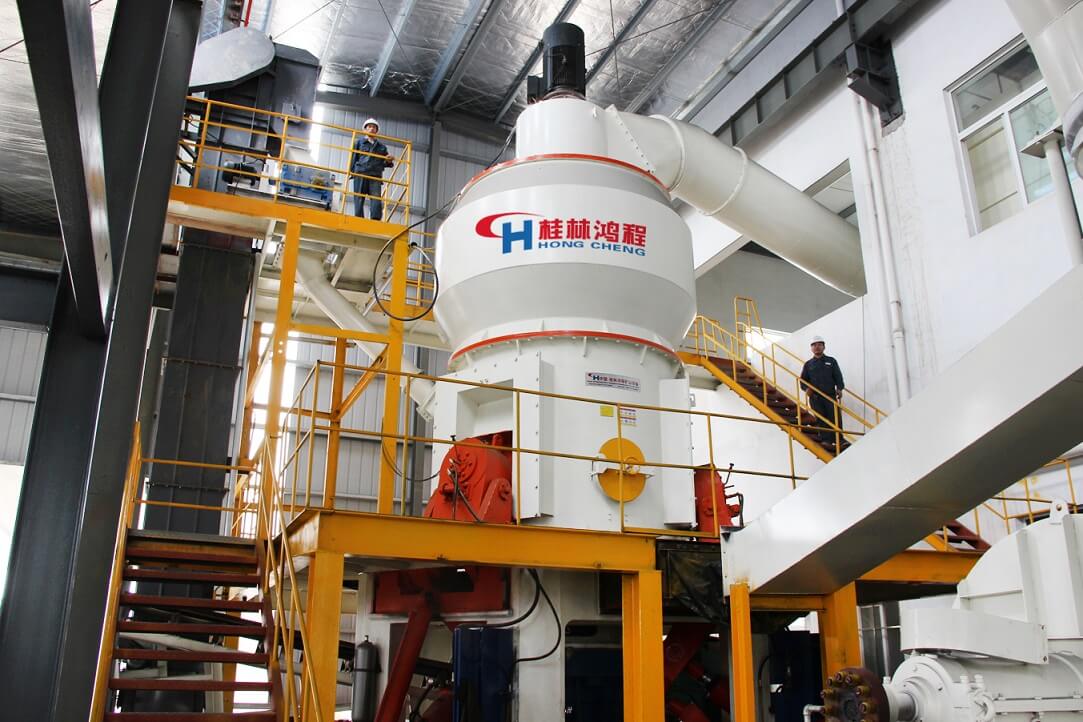

In order to achieve the purpose of energy conservation and emission reduction, the application of vertical mills for preparing pulverized coal in cement plants breaks the long-standing traditional concept in the cement industry that only ball mills can be used to prepare anthracite pulverized coal, creating conditions for cement companies to further save energy and reduce costs. Guilin Hongcheng is a manufacturer of vertical coal grinding mills for cement plants. Today we will introduce to you the application of vertical coal grinding mills in the preparation stage of pulverized coal in cement plants.

Coal Pulverized Vertical Grinding Mill, welcome to leave a message or consult [email protected]

Bituminous coal is generally used in rotary kilns, while anthracite is a low-reactivity fuel and is mostly used in shaft kilns. Anthracite coal is widely distributed and often cheaper than bituminous coal. At present, the cement industry believes that vertical mills cannot grind anthracite coal powder. Most rotary kilns that use anthracite as fuel grind anthracite through ball mills. However, the unit power consumption of ball mill is high and the medium wear is large. As the output of new dry process cement becomes higher and higher, how to use vertical coal mills in cement plants to prepare anthracite and low-grade coal has become an important topic in the research of new dry process cement production technology.

Based on the HLM vertical mill, Guilin Hongcheng optimizes the high-fine coal grinding process and equipment based on the characteristics of anthracite and inferior coal. Its goal is to research and develop a vertical coal mill for cement plants that has independent intellectual property rights, meets user requirements, and meets the requirements for burning anthracite and inferior coal pulverized in new dry process cement clinker production lines.

The fineness of pulverized coal has a great influence on the combustion process of coal. Fine pulverized coal is conducive to improving the combustion activity of coal and making coal fully burn. The purpose of preparing pulverized coal is to make coal burn quickly. Therefore, anthracite coal and low-quality coal with poor reactivity are ground finer than bituminous coal. That is, coal with poorer reactivity requires finer grinding fineness. The fineness of high-quality bituminous coal entering the kiln is generally controlled at 80 μm and the moisture content is<1%. The fineness of bituminous coal should be controlled at <6%. For anthracite with a volatile content of 3% to 8%, the grinding fineness should be controlled at 80 μm. The vertical mill for preparing pulverized coal in cement plants should dry the raw coal containing a certain amount of moisture and grind it to the required fineness. The vertical mill for preparing pulverized coal in the cement plant reduces the material movement speed, which is beneficial to the stability of the material layer on the grinding disc; the technology of reducing the grinding disc speed and increasing the grinding roller pressure ensures stable operation and high mechanical efficiency when grinding anthracite and inferior coal; epitaxial The grinding roller bearing adopts a sealing method to isolate the relatively moving parts of the roller shaft and the transparent cover from the dust-containing gas in the grinding chamber. The sealing is reliable and the structure is simple; the short-circuit-proof dynamic and static combined separator improves the powder selection efficiency and ensures product fineness. Compared with the ball mill for vertical coal preparation in cement plants with the same specifications and capabilities, the investment is 10% to 20% higher. However, based on the calculation of a cement clinker production line with a daily output of 2,500 tons, the vertical mill only saves electricity costs and can save higher investment in more than a year. The medium wear of vertical mill is 5~10g/ton of pulverized coal, and that of ball mill is 100g/ton of pulverized coal. In addition, the vertical mill occupies a small area, can be arranged in the open air, and has a small building area. Obviously, the cost of use is It is lower than ball mill.

When grinding anthracite and low-quality coal, the cement plant coal pulverized preparation vertical mill controls the pulverized coal particle size at 80 μm, which can meet the production process requirements of new dry cement rotary kiln firing and other industries. The overall structure is reasonable, the operation is stable, and the control It is reliable, easy to operate, and has obvious power saving effect. The main technical and economic indicators of this achievement have reached the international advanced level.

The application of vertical mills for preparing pulverized coal in cement plants enables more extensive utilization of anthracite and inferior coal, which is of great significance to the utilization of inferior fuels in the cement industry and other industries, and has significant economic and social benefits. If you have relevant needs, please leave us a message to learn more about the equipment.