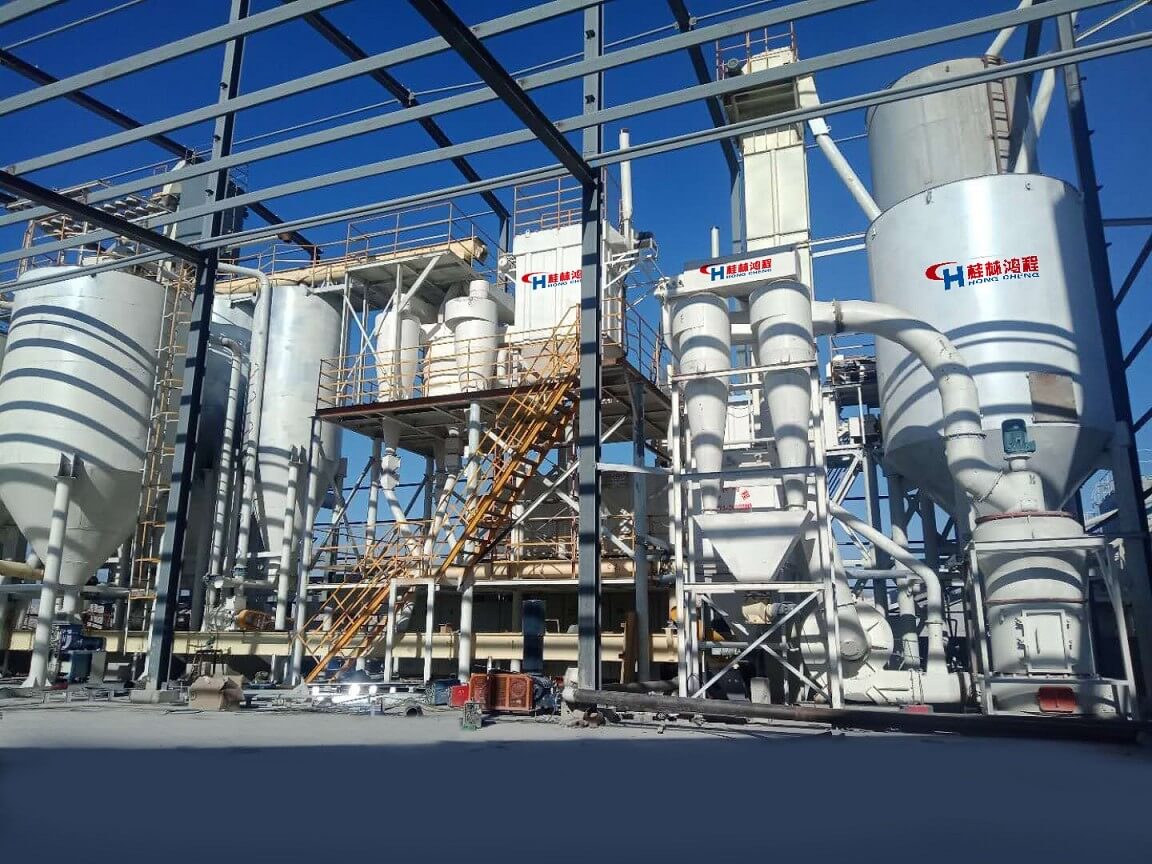

The production process of calcium hydroxide mainly includes wet method and dry method. Due to the simplicity of dry method and small investment, fully automatic production can be realized, the production process is environmentally friendly, the products are diversified, the output is high, and the quality is stable. The calcium hydroxide products produced With no impurities and good activity, it has replaced the old-fashioned wet production and has become the mainstream processing technology. Guilin Hongcheng is a manufacturer of a complete set of calcium hydroxide grinding mill equipment. We supply a complete set of equipment for the production of calcium hydroxide of 5-20 tons, and have been successfully applied in the market. Today, I will sort out the production raw materials, production equipment, various products and production processes of dry process calcium hydroxide for you, and jointly promote the progress of calcium hydroxide production.

Complete calcium hydroxide production line, welcome to leave a message or consult [email protected]

1. Raw materials for calcium hydroxide production: There are many varieties. One is active lime (activity greater than 350), which is mainly produced by rotary kilns and wheat kilns. It is characterized by good quality and high purity, and generally available calcium is greater than 90. There are also some high-end special products, especially medicinal calcium and food calcium, which require the limestone content of the raw material to meet the standard, and are manually selected by special calcination methods to meet the requirements. Second, ordinary lime includes shaft kiln lime, underscreen ash of rotary kiln and wheat kiln, the general activity is about 250-300, and the content of effective calcium is more than 85%. The third is most of the limestone fired with a calcium oxide content below 52, including the low-grade lime with an active degree of about 200-250 and an effective calcium content of less than 80 that have problems during the firing process, plus some The leftovers left in the process of producing high-quality calcium hydroxide, the leftovers left by light calcium nano-calcium manufacturers, carbide slag, etc. Various raw materials are used to produce calcium hydroxide products of various indicators to meet the needs of various customers in various industries.

2. Requirements for the calcium hydroxide digester of the main machine of dry calcium hydroxide equipment: According to the requirements of lime digestion, the higher the temperature in the production process, the better, and the high temperature can discharge steam quickly and efficiently. Only by adding more water and discharging more water can the water content of the product meet the standard, and enough water can be fully mixed with the lime so that each lime can be mixed with water to achieve maximum digestion, and the digestion time should be flexible, controllable and adjustable, and the digestion control system Be advanced. When lime is digested, it will cause many unstable factors due to various reasons. If the control system is outdated, it will cause jamming, unstable content, fineness, and moisture content, etc. The utilization rate of lime is also low and the production cost is high. All in all, to choose a digester, you need to evaluate your company's raw materials and products, and choose a set of digestion equipment that suits you, so as to create greater benefits for the company. At present, the common calcium hydroxide digesters are as follows:

(1) Push-in type: This kind of digester has a built-in push-in oblique blade, which is narrow and long in appearance. Its characteristics can effectively adapt to lump ash of various particle sizes and leftovers, carbide slag and various waste materials that can be mixed with light calcium nano-calcium, so that raw materials with poor fluidity can be produced normally, and the digestion temperature is high to promote lime digestion. It can increase the detection content of calcium hydroxide, especially suitable for the production of high moisture content, high specific surface area and high active ash. At present, the proportion of enterprise use is the highest.

(2) Self-flowing type: This kind of digester is equipped with up and down turning rods, and its appearance is wider and shorter. It is suitable for high-quality lime with small particle size and low burnt. In the next production process, the undigested product is digested at the bottom of the digester. If the raw material is overcooked and the space at the bottom is filled up, it will lose its advantage. Moreover, the digestion temperature is not high, so it is not suitable for adding various scraps with poor fluidity. materials, so the requirements for raw materials are higher.

(3) High-quality formula: The production of calcium hydroxide for medicine and food not only has particularly high requirements for raw materials, but also strict requirements for the process of production and digestion. Digestion should be moderate, and over-digestion will burn lime as well. Digestion, burnt lime is yellow-black in color, and the particle size of natural digestion is rough, so raw burnt lime must be separated in time during the digestion process to meet the requirements of whiteness, fineness, high content and less impurities.

(4) Messy type: Some calcium hydroxide enterprises find repairmen to process by themselves in order to save money, and some imitation enterprises that do not know enough about the production process of calcium hydroxide in machinery factories have produced some various digesters, which make many production of hydroxide Calcium enterprises have caused a lot of losses.

3. Equipment requirements for grinding calcium hydroxide: fineness is also an important indicator in calcium hydroxide products. At present, the common calcium hydroxide dry grinding equipment includes powder separator, all-in-one machine, ultrafine mill, ash calcium machine, etc.

(1). Powder classifier: At present, it is the most reasonable and energy-saving model. But it is different from those used in other industries such as cement and heavy calcium. Due to the characteristics of calcium hydroxide, such as light weight, viscosity, high water content, high temperature, and many varieties, the powder concentrator must adopt the characteristics of large air volume, high classification, large pipeline, tight sealing, and easy adjustment. Try to achieve the effect that there is no roughness in the thick, but no thick in the thin. Achieve high calcium hydroxide content, less impurities, light specific gravity, high specific surface area, and stable quality.

(2). Calcium hydroxide grinding integrated machine: it is a calcium hydroxide production model launched by Guilin Hongcheng in recent years. It is characterized by feeding digested calcium hydroxide into the machine through the spreader If the fineness reaches the standard, it is first selected into the product, and the rough one falls to the lower mill and then grinds to the standard before being selected into the product. For example, the production of products with low requirements can be done, because raw coal slag and other impurities will be ground into the product through grinding, and the wear-resistant parts and electricity costs are relatively high. Its main disadvantage is that the design of the powder selection system is too small, which inherits the grinding The characteristics of heavy calcium, there is no characteristic for calcium hydroxide.

(3) Ultra-fine grinding: it is mainly aimed at products with high fineness, the number of mesh is more than 1000 mesh, it is also modified from other industries, so if you want high quality and high fineness, you must add a powder selection system before grinding , first remove the quality and then grind it finely. It cannot only have high fineness without high quality. Its disadvantages are low output and high power consumption.

(4) Ash calcium machine: The feature of this machine is that through high-speed operation, the materials can collide with each other to form fineness, and the qualified products can be sent to the product warehouse through powder selection and wind, so that the impurities that cannot be collided into fine powder can be removed. . Its specific meter, activity, slag discharge, and air delivery are incomparable to other equipment, but the output is small, and the maintenance of the machine itself is difficult due to the fast speed. There are also some imitated various equipment on the market now, but the effect is not good.

The above is the detailed explanation of the complete set of equipment and process for dry production of calcium hydroxide. As a manufacturer of a complete set of calcium hydroxide equipment, Guilin Hongcheng provides a complete set of customized calcium hydroxide production lines. With the advancement of intelligence and the improvement of equipment, the production of calcium hydroxide will surely achieve full automation, unmanned and dust-free modern production. If you want to know the price of the full set of calcium hydroxide equipment, or need to visit the site of the full set of calcium hydroxide equipment, you can leave us a message to learn about the customized solution of the full set of calcium hydroxide equipment.