Since the grinding requirements of petroleum coke are closely related to the combustion characteristics, its combustion characteristics are slightly worse than those of anthracite, so the grinding fineness requirements are very high. Therefore, the research and development of petroleum coke vertical grinding system has very important practical significance. As a manufacturer of petroleum coke vertical mills, Guilin Hongcheng will introduce to you the design of petroleum coke vertical mill systems.

Petroleum Coke Vertical Grinding Mill, welcome to leave a message or consult [email protected]

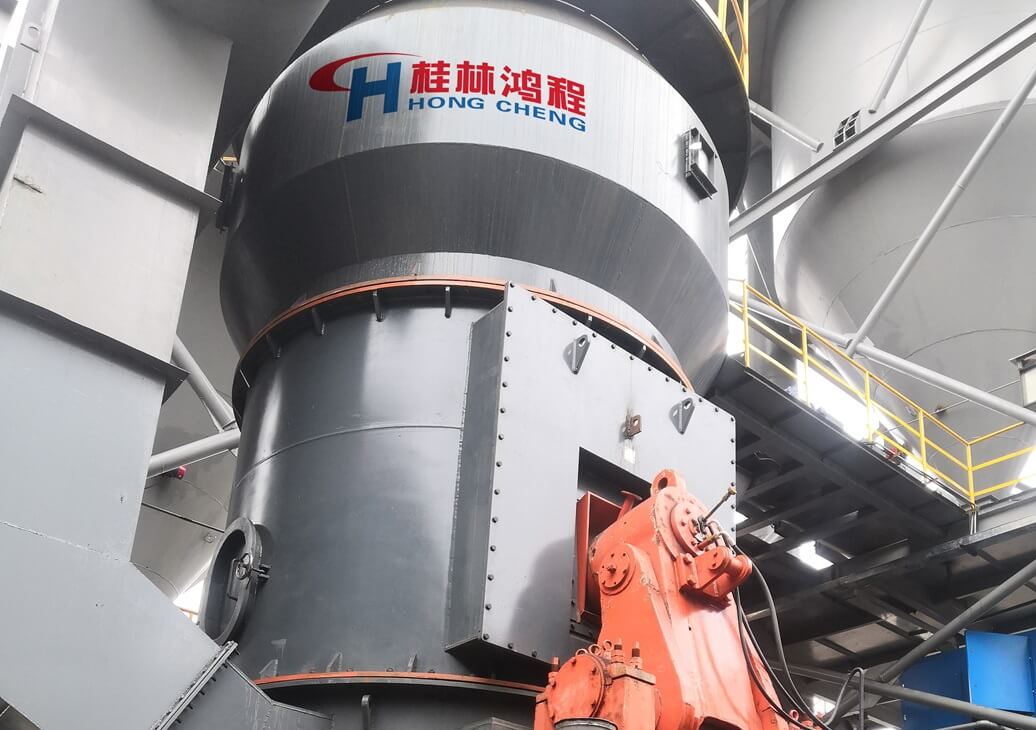

Guilin Hongcheng HLM series petroleum coke vertical mill is mainly composed of frame body, transmission part, grinding disc, grinding roller, tensioning device separator, sealed air pipeline and other parts.The density of petroleum coke is small. To ensure the cutting particle size, the separator must be optimized and designed so that the cutting particle size is guaranteed when the separator speed is within a certain range. After years of optimizing the design of the petroleum coke vertical mill system, we have summarized the solutions to the technical difficulties of vertical mill petroleum coke grinding as follows:

1. Increase the grinding pressure and reduce the number of times the material is ground;

2. Increase the radius of curvature of the grinding disc and roller to increase the contact area of the grinding disc and roller and increase the grinding area;

3. Use an adjustable retaining ring to adjust the time the material stays on the grinding disc;

4. Add a water spray mechanism (adopting the structure of a slag mill water spray device) to further stabilize the material layer;

5. Design a high-efficiency separator to improve powder selection efficiency, and adopt reverse blade sealing technology;

6. An inclined tie rod is used, and the center of the frame is at a certain angle to the horizontal, so that it forms a horizontal component to slow down the vibration of the mill, and the tie rod seal is designed accordingly. Because it is a negative pressure operation, the tie rod sealing form can refer to the tie rod sealing form of the raw material mill.

7. Add a grinding roller anti-collision block to limit the position of the grinding roller to prevent damage to the connecting bolts between the roller bracket and the pressure frame.

In addition, although the ignition temperature of petroleum coke is relatively high, it is still possible to catch fire under oxygen-rich conditions. Therefore, the oxygen content of the hot gas entering the mill must be controlled during design, and at the same time, inert gas must be added into the cylinder; a CO online detector must be installed in the system and a fire extinguishing system must be configured.

In view of the characteristics of petroleum coke itself, in the design of the HLM petroleum coke vertical mill system, corresponding solutions were taken based on the technical difficulties of low density of petroleum coke and high requirements for finished product fineness. Judging from the commissioning situation, the design and operation of the Hongcheng petroleum coke vertical mill system are in good condition. Its main technical indicators have reached or exceeded the design values, and users are also quite satisfied with the usage. If you have petroleum coke vertical grinding system design requirements, please leave us a message for details.