Limestone is a key raw material for producing cement, concrete aggregates, lime, calcium carbonate, and more. Its crushing and grinding typically use dry processing, and the appropriate methods are chosen based on different application fields. As a manufacturer of limestone grinding equipment, Guilin Hongcheng is here to provide you with a detailed introduction:

For limestone used in metallurgy and road construction, the ore is generally crushed and screened for direct use.

For fine powder products used as feed additives and general fillers, the ore is usually crushed using various crushers like jaw crushers, hammer crushers, and impact crushers, and then ground using Raymond mills, vertical mills, roller presses, or impact mills.

For ultra-fine limestone powder used in flue gas desulfurization and high-grade fillers, ultra-fine grinding and precise classification are typically required, and the equipment used is similar to that for ultra-fine grinding of calcite.

Currently, most limestone powder used in the building materials industry is ground from limestone or stone chips generated during aggregate production to meet specified fineness requirements.

Limestone Grinding Process Flow

The limestone grinding process mainly includes two types:

Open Circuit Process: This is where the material passes through the mill once and is considered a finished product for the next operation.

Closed Circuit Process: In this process, the material is classified after leaving the mill, with fine particles as the finished product and coarse particles returned to the mill for re-grinding.

The open circuit process is relatively simple and has advantages such as fewer equipment, lower investment, and ease of operation. However, since all materials must meet fineness requirements before leaving the mill, over-grinding can occur, and finely ground materials can form a buffer layer, hindering further grinding of coarse materials, significantly reducing grinding efficiency and increasing energy consumption.

Therefore, most limestone powder manufacturers currently choose the closed circuit process, which can reduce over-grinding, improve mill efficiency, and lower energy consumption. Additionally, limestone powder produced using the closed circuit process has a uniform particle size and is easy to adjust, meeting different fineness requirements.

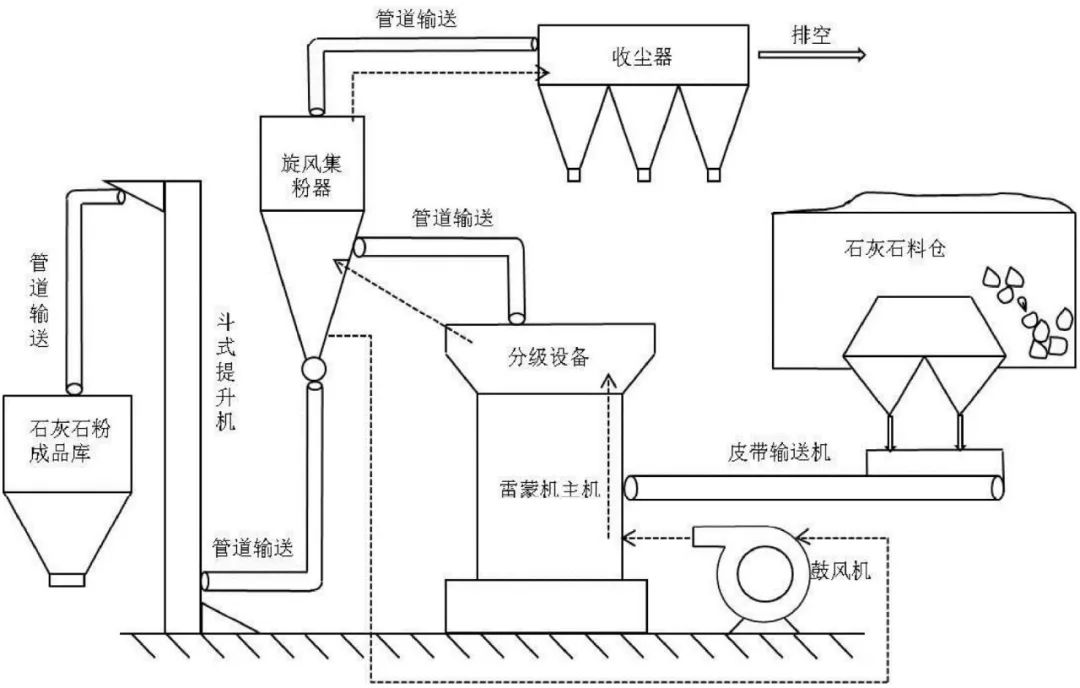

Closed Circuit Production Example of Limestone Powder Using mond Mill

Process Description:

Limestone falls from the bottom of the feed bin onto a belt conveyor, which then sends it to the mill for grinding.

Due to centrifugal force, the grinding roller tightly rolls on the grinding ring, with the scraper lifting the material into the space between the roller and the ring, where it is crushed into powder under the grinding pressure.

The ground material is blown out by the fan and classified by the classifier above the mill.

The classifier consists of a radial blade wheel and a drive device. The blade wheel is driven by the drive device to rotate at a certain speed, allowing coarse particles in the airflow to fall back for re-grinding while fine powder passes through the air screen to the cyclone separator, thus performing a screening function. Adjusting the air volume or changing the blade wheel speed allows for free adjustment of the powder particle size.

The cyclone separator separates qualified products from the air, with finished products transported to the finished product warehouse via a bucket elevator, while the airflow is returned to the fan for recycling.

The material contains a certain amount of moisture, which generates water vapor during grinding. Due to the not entirely sealed system, some external gas is drawn in, increasing the system's circulating air volume. To ensure the mill operates under negative pressure, excess airflow is purified by the bag filter and discharged into the atmosphere.

As a manufacturer of limestone grinding equipment, Guilin Hongcheng has extensive experience in designing limestone grinding processes, including various solutions such as Raymond mills, vertical mills, and ring roller mills. If you have any related grinding project needs, feel free to contact us for more details. You can reach our representative, Mr. Jiang, at:[email protected]